|

Connector A

|

MPO

|

Connector B

|

MPO

|

|

Patch cord type

|

Trunk patch cord

|

Fiber number

|

8 cores

|

|

MPO IL

|

Standard loss

|

Polishing

|

PC

|

|

Connector housing color

|

Green

|

Connector boot type

|

Mini round cable boot

|

|

Connector type

|

Female/male

|

RL (return loss)

|

≥60dB

|

|

IL(Typical)

|

0.2dB

|

IL(Max. value)

|

0.75dB

|

|

Compatible optical transceiver

|

QSFP+PLR4(40G),QSFP28 PSM4(100G),OSFP DR4/XDR4(400G),QSFP-DD DR4/XDR4(400G)

|

Tolerance

|

+6cm

|

|

Cable diameter

|

3.0mm

|

Cable color

|

Yellow

|

|

Cable jacket material

|

LSZH

|

Flame retardant grade

|

OFN(standard) ; OFNR/OFNP(optional )

|

|

Fiber brand

|

YOFC

|

Fiber type

|

G657A1

|

|

Working wavelength

|

1310&1550nm

|

Fiber loss

|

≤0.35db@1310nm/≤0.2dB@1550nm

|

|

Min.bending radius(short term)

|

10D

|

Min.bending radius(long term)

|

20D

|

|

Polarity

|

TYPE A/B/C/others

|

Durability

|

≥500 times

|

|

Operating temperature

|

-10 to 70℃ (14 to 158℉)

|

Storage temperature

|

-40 to 85℃ (-40 to 185℉)

|

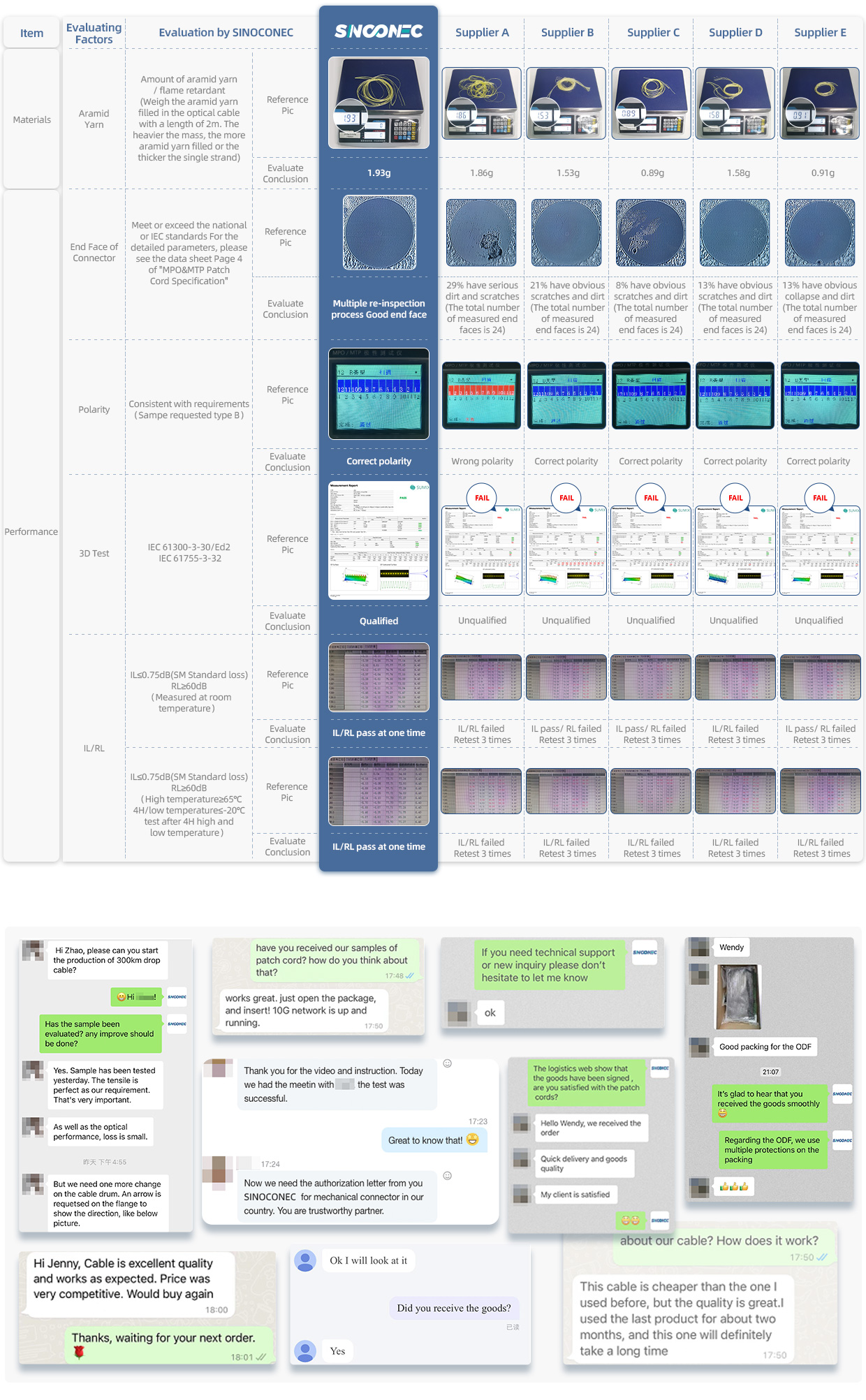

The SINOCONEC factory has 5 MPO/MTP production lines with a daily MPO capacity of 5,000 ends. The production line has several sets of internationally recognized production equipment, Polishing using Domaille Polishing machine. In order to ensure quality, stability and environmental protection requirements for all MPO connectors, consumables use Fujikura ribbon forming adhesive, EPO-TEK 353ND adhesives, MIPOX Polishing/Abrasive Film. To ensure reliable and reproducible SINOCONEC MPO jumper test results, the production line uses SUMIX, JGR and other brand equipment for testing. In addition, SINOCONEC sets up double checks for both polarity and end face tests to ensure excellent product quality. SINOCONEC owns a holding sheet metal processing and production plant, which can provide high-quality and low-cost optical fiber distribution frame products.

Ann

Ann